|

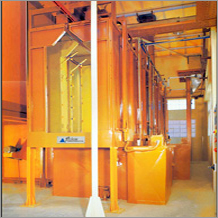

Dip pretreatment - tank arrangement

Product Details:

Product Description

Dip pretreatment - tank arrangement

Prism's advanced multistage pretreatment systems are perfectly suited for both batch and continuous operation. These perform a through cleaning of all metal parts to be processed, and provide superior corrosion protection. Reducing effluent load uses cascaded ranges for water conservation, there. Clean bath and bath life is achieved by incorporating continuous oil separation and phosphate sludge separation system. Flexible nozzles ensure easy adjustment of spray direction and air pocket direction. Quick release pipe coupling and nozzles aid easy maintenance. Advanced F.R.P/S.S. systems are compatible with all solutions and therefore off high chemical resistance and prevention of mechanical damages, CHROME Free post pretreatment (de-ionized water rinse) facilitates better sealing. Water treatment plants are effectively employed to treat the effluent and they conform to local statuary requirements.

Prism offers CLEMCO'S grit blasting facility/grit recovery systems for removal of heavy MIL SCALE and rust, especially in H.R steel sections, for effective surface preparation prior to painting/powder coating with or without post dip/spray pretreatment.

Surface preparation can be done by multistage operations .The most commonly used multistage operations are 3 stage and 5 stage by following ways.

Spray wand application: This method of pretreatment employs the use of an electrical motor to power a pump providing pressurized solution through a heating coil to a hose and hand held wand assembly.

The heat is providing by oil or gas fired burner to a heating coil that is part of this stand-alone system.

- Advantages : Can be used for large and bulk components.

- Disadvantages : Skilled labors required for troubleshooting.

Immersion system: This process is dipped process, which employs one or more tanks

That holds solution in which the parts are batched or process dipped continuously via overhead conveyor. This is basically preferred for batch process .

Advantages :Simple to maintain, low capital cost, prolonged chemical contact time is possible complete contact with chemical solution and more flexible chemistries can be used.

Disadvantages: Suits for batch process only.

Re-circulating spray process: This the most preferred pretreatment process used in the industry as it has better efficiency. This process reduces the waste management systems.

Advantages: High efficiency levels of cleaning and conversion possible. Recirculation keeps the part in contact with fresh solution. Process time can be shortened energy saving is possible.

Disadvantages: High capital and maintenance cost. Trouble shooting techniques requires expertise.

Other Products in 'Pre Treatment' category

Branch

Office : Chennai

Plot

No. 1388, 1st Block, 10th Street,

Off.

18th Main Road, Anna Nagar (West),

Chennai

- 600 040

|

|

|

|

PRISM SURFACE COATINGS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |