|

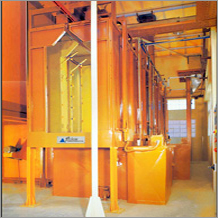

Heating Systems

Product Details:

Product Description

Heating Systems

Some of the heating methods available are immersion tanks, plate coils and plate and frame heat exchangers. Immersion tubes are long tubes along the floor area of the tank. Heat transfer takes place along the surface of the tubes. The fuels used for this type of heat source are propane, LPG, HSD and LSD. The plate coils are very cost effective if there is an existing steams source available in the plant. These are immersed inside the tank and the steam is sent thro the tubes.

SCADA is the abbreviation for Supervisory Control And Data Acquisition. It generally refers to an industrial control system which is meant to function across a wide area with an autonomous Remote Terminal Unit (RTU).

The precise definition of SCADA has been muddied somewhat by newer telecommunications technology, enabling reliable, low latency, high speed communications over wide areas, and a tendency by popular media to mistakenly refer to all Industrial Control Systems as SCADA. Despite this confusion, a SCADA system is expected to have open loop controls (meaning that a human operator watches near real time data and issues commands). By comparison, a Distributed control system (DCS) is expected to have closed loop controls (meaning that real-time loop data is applied directly to an industrial controller without human intervention). These differences are primarily design philosophies, not mandates of definition.

The supervisory control system is a system that sends commands to a real-time control system to control a process that is external to the SCADA system (i.e. a computer, by itself, is not a SCADA system even though it controls its own power consumption and cooling). This implies that the system coordinates, but does not control processes in real time, as there is a separate or integrated real-time automated control system that can respond quickly enough to compensate for process changes within the time constants of the process. The process can be industrial, infrastructure or facility based as described below:

The supervisory control system is a system that sends commands to a real-time control system to control a process that is external to the SCADA system (i.e. a computer, by itself, is not a SCADA system even though it controls its own power consumption and cooling). This implies that the system coordinates, but does not control processes in real time, as there is a separate or integrated real-time automated control system that can respond quickly enough to compensate for process changes within the time constants of the process. The process can be industrial, infrastructure or facility based as described below:

Industrial processes include those of manufacturing, production, power generation, fabrication, and refining, and may run in continuous, batch, repetitive, or discrete modes.

Infrastructure processes may be public or private, and include water treatment and distribution, wastewater collection and treatment, oil and gas pipelines, electrical power transmission and distribution, and large communication systems.

Facility processes occur both in public facilities and private ones, including buildings, airports, ships, and space stations. They monitor and control HVAC, access, and energy consumption.

Other Products in 'Pre Treatment' category

Branch

Office : Chennai

Plot

No. 1388, 1st Block, 10th Street,

Off.

18th Main Road, Anna Nagar (West),

Chennai

- 600 040

|

|

|

|

PRISM SURFACE COATINGS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |