|

Grit Blasting

Product Details:

Product Description

Grit Blasting

Our business associate CLEMCO INTERNATIONAL GMBH is the European headquarter of Clemco Industries the world's largest manufacturer of air-powered blast equipment used to clean, deburr, shot peen, remove coatings, finish or otherwise improve the surface being blasted

Surface Preparation

- Blasting equipment

- Compressor (Air requirement)

- Pressure pots

- Remote valves

- Blast hose

- Blast nozzles

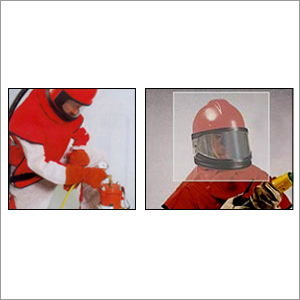

- Protective clothing & helmet

Abrasives

- Types of abrasives

- Abrasive recovery system

- Blasting is a process in surface preparation for cleaning metal objects free oil and rust and leaves the surface ready for painting or bonding.

Types of Blasting

- Centrifugal blasting

- Wheel type

- Pressure blast or pot blast

- Open blasting

- Closed blasting

Surface Preparation

- Roughness - anchor profile

- Cleanliness

Anchor Profile

Coating requires specific profile to ensure adhesion and complete protection of the substrate. The abrasive particles cut into steel to form tiny peaks and valleys. The depth of the profile is controlled by the size, type & hardness of the abrasive used.

For instance in ship repair the etched surface or "anchor profile" required will be about 125 microns using the grit size of 0.5 to 2.5 mm.

Cleanliness

The steel structures painting council (SSPC) has established four degree of cleanliness for blasting for removal of contaminants and loose materials on the surface

- White metal blast - SA -3

- Near white metal blast. - SA - 2.5

- Commercial blast - SA - 2

- Brush - off blast - SA - 1

Blast Nozzles

Area of Coverage FOT SA - 2 1/2 Finish

| 6 mm Nozzle | 10 Sq Mt / Hr |

| 8 mm Nozzle | 15 Sq Mt / Hr |

| 9.5 mm Nozzle | 22 Sq Mt / Hr |

| 11 mm Nozzle | 32 Sq Mt / Hr |

| 12 mm Nozzle | 40 Sq Mt / Hr |

Other Products in 'Grit Blasting' category

Branch

Office : Chennai

Plot

No. 1388, 1st Block, 10th Street,

Off.

18th Main Road, Anna Nagar (West),

Chennai

- 600 040

|

|

|

|

PRISM SURFACE COATINGS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |